Automatic Butyl extruder Machine With High Speed Hot Melt Butyl

Extruder Machine

Application of Automatic Bulyl Extruder Machine

Fast preheat,improve work efficiency

with preheating function

With exhaust and inflatable function,improve coating quality and

asve time for feeding glue

Quickly coating speed,can up to 47m/min

PLC control system,touch screen interface

Automatically adjust the amount of glue according to different

speeds

Automatically identify the width of aluminum bar,accordingly glue

nuzzle can adjust automatically.

Hydraulic systerm uses German components to ensurethat the glue is

even and full

Squeeze pressure:10-18MPa

Temperature:110-140℃

Aluminumspacerwidth:6A-27A

Speed:5-47m/min

Diameter of butyl cylinder:200mm

Air supply:0.4㎡/min

Air pressure:>0.6Mpa

Total power:380V,5.7KW,50HZ

Dimension:2800*700*900mm

Weight:650kg

Tech parameters of Automatic hot melt Extruder Machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 0-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 750kg |

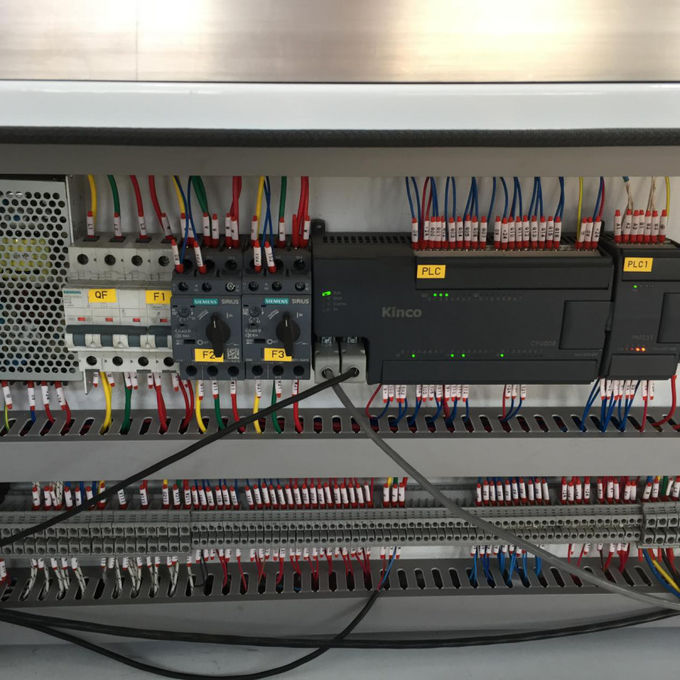

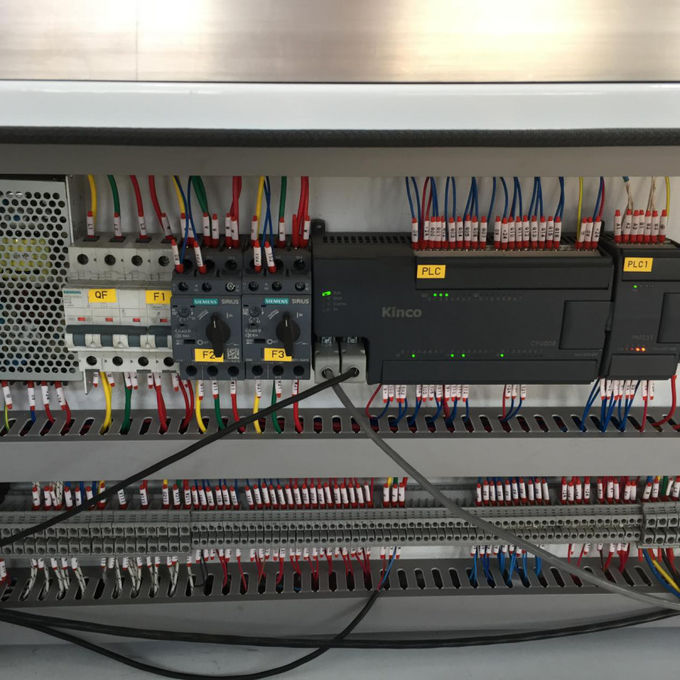

Equipment details of Automatic Butyl Extruder Insulating Glass machine

Germany Siemens parts

Butyl extruder machine Adopt German brand Siemens PLC, stable

performance.

KINCO Touch Screen

Use toubh screen operation ,simple trial,Clear interface, Simple

operation, Smart touch screen,Updated programming.

Germany HAVE Valve

High speed butyl extruder machine Adopt Germany’s Harvey valve,

more stable performance.

Alarm system

Adopt Automatically alarm system, reminding adding butyl.

Glue cylinder

The rubber cylinder adopt the pull-up structure, which is

convenient for changing butyl.

Other product of LIJIANG GLASS

Spacer Bending Machine With Aluminum Bars And Warm Bars

Application

The full automatic spacer bending machine is used for making frames

( or other materials) for insulating glass, which replaces the

traditional fabrication technology. The Automatic Spacer Bending

Machine With Aluminum Bars And Warm Bars can make a variety of

convex polygonal aluminum frames by one aluminum strip in one time.

The bending machine is available to bend aluminum bars, stainless

steel bars, warm bars and thermex and so on. Also on the bending

mahcine, also contains printing code , printing label , drilling

holes and USB, machine hand for support big frame

Equipment details

- Adopt Siemens PLC control system, touch screen interface

- Japan FUJI CNC servo control system

- Four spacer size storage units

- Aluminum spacers are available in different sizes and sizes

- Automatically cut and feed aluminum spacers

- Bend shaped spacer frames continuously

- Automatically avoid the connecting corner while bending and cutting

- The special machine hand device is used to bend big spacer frame

- Heavy duty connectors is convenience and safety for installation

and debugging

- Taiwan Airtac Magnetic valve; German Siemens PLC control system;

Japan Fuji servo control system.

- Spare parts of all machine have ID codes.

- Precise bending effect, corner error less than 0.1mm.

Leading Technology

- Spacer printing code function (Optional)

- Automatic drill gas filling hole (Optional)

- Printing label sticker function (Optional)

- USB input function, read the excel format file directly etc (Optional)

- Connect to ERP system (Optional)

- Can bend aluminum spacer ,Technoform, Alupro, Thermix, warm spacer

(Swisspacer) and stainless steel ( Optional) and so on.

- We have the special soft system which could avoid the 120mm to

reduce waste. For example, if the length of the gusset is 60mm,

when the program calculates the right angle, there is a gusset.

When you start to bend the rectangular frame, you need firstly

transport 120mm, then cut 120mm, and then step on the pedal to bend

frame, so you will waste the 120mm.

Technical data

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Electrical parameters

| NAME | BRAND | NAME | BRAND |

| PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

| Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

| Servo motor | JAPAN FUJI | Solenoid valve | Taiwan AIRTAC |

| Servo driver | JAPAN FUJI | Switch power | Taiwan TEND |

| Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

| Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |

Other products of LIJIANG GLASS

Automatic desiccant filling machine for making insulating glass

processing machines

Main feature

• Adopt Siemens PLC control system

• Molecular sieve can be 0.5 – 0.9mm or 1.0 – 1.5mm sizes

• Touch screen interface, simple and visible

• The machine height can be adjusted according to the size of

spacer frame

• Automatically loading and replenish molecular sieve

• Double tubes for unloading to increase filling speed

• Filling time can be adjusted

• Automatically drilling, filling and sealing

• Core parts are imported brands

• Using big plastic barrel, save feeding time and improve

efficiency (Optional)

• Protection device for machine head (Optional)

• Filling arc frame (Optional)

Technical data

| Max. frame size | 2000mm*2000mm (2500mm*2500mm) |

| Min. frame size | 300mm*250mm |

| Aluminum specifications | 6A- 27A |

| Air source | ≥0.65MPa |

| Power supply and power consumption | AC220V 50Hz 1KW |

| Molecular sieve diameter needed | 0.5-0.9 mm or 1.0 – 1.5mm |

| Dimension | 1100mm*1100mm*3600mm |